A welder who suffered carbon monoxide poisoning at Seaspan’s Victoria shipyard continued to cut metal in a confined space on a ship for 40 minutes after a gas-monitor alarm started sounding, says a WorkSafeС����Ƶ report.

Seaspan has been fined just over $710,000 for “high-risk violations” in connection with the July 12, 2023, incident at the Admirals Road shipyard.

The incident report said a gas-monitor alarm started sounding about two minutes after the worker started cutting metal inside the confined space, where he was doing arc gouging — a welding technique using a carbon electrode, power and compressed air to create intense heat to melt and cut metal.

The report said the alarm should have led to an immediate evacuation, but the cutting of metal continued for 40 minutes before the worker finally emerged on his own.

“There was no action taken to pull the worker out of the space where there was carbon monoxide buildup.”

WorkSafe said Seaspan failed to have a standby person stationed outside the confined space who should have been monitoring the gas buildup and informing the worker every 10 minutes.

Confined-space permits require workers and standby personnel to use radios and visual signals to communicate during work in confined spaces.

“None of those were actually used while the alarm was going off,” said the WorkSafe report. “The employer stated that the standby person had not received training for the duty he was performing.”

The standby person was not at the entrance for at least 40 minutes, the report said. “When the worker exited the space following their injury, the standby person was not there.”

The report said Seaspan did not ensure that adequate personal protective equipment was used in the confined space. It said a “half-face respirator” with ineffective filtering for carbon monoxide was used because the required respirator with a compressed-air line was not in working condition.

Seaspan told WorkSafe inspectors it could not retrieve the data from its carbon monoxide monitor, so there was no indication of the CO levels during the 40 minutes that the worker was inside the confined space while the alarm was sounding.

Paramedics transported the worker to hospital after the incident. The severity of the worker’s injuries was redacted from the inspection report provided to the Times Colonist by WorkSafe.

An inspection by WorkSafe identified several deficiencies with Seaspan’s confined-space entry program, saying it failed to do a hazard assessment of the confined space’s design, use and work activity inside it.

WorkSafe said Seaspan failed to ensure confined-space testing was done by a qualified person, failed to keep adequate test records and did not do additional testing while a worker was inside the confined space.

WorkSafe’s maximum penalty for 2024 is $783,068.26. The penalties are usually based on the size of an employer’s payroll and the type of violation, and amounts are adjusted by legislation every January.

In Seaspan’s case, the regulator said “these were all high-risk violations.”

WorkSafe issued several orders related to occupational health and safety under the Workers Compensation Act. In a March report, some orders were closed because specific work had stopped at the shipyard. However, more action was required on risk assessment and atmospheric testing.

The inspection report said protective equipment training had been completed.

Seaspan Victoria Shipyards said in a statement the company is committed to the safety of employees and contractors.

“Following the incident at Seaspan Victoria Shipyards last July, we have taken a number of actions to evaluate and improve our processes and safety culture,” said the statement.

“We constantly review our safety programs and hold ourselves accountable to achieve a safety culture across our organization.”

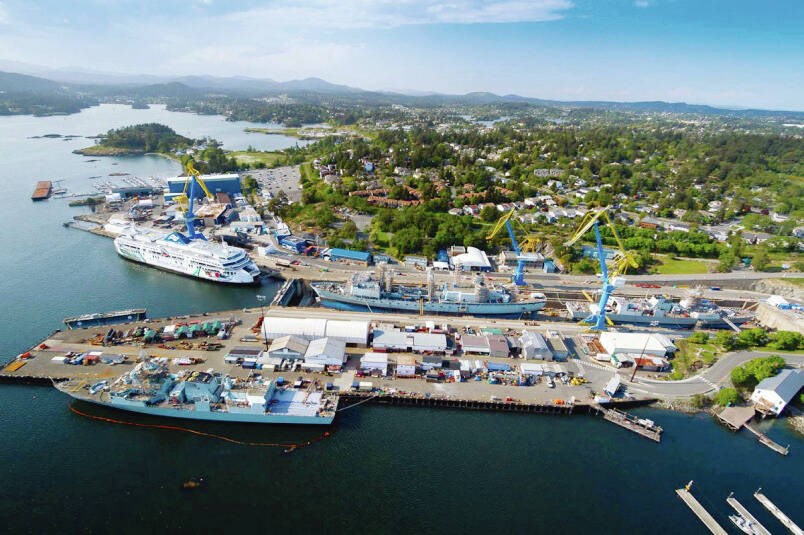

Seaspan Victoria Shipyards calls itself the leading ship repair and modernization facility on Canada’s west coast, specializing in complex projects involving government and commercial partners.

It is part of the Royal Canadian Navy frigate and submarine maintenance programs.

>>> To comment on this article, write a letter to the editor: [email protected]